About Us

- Home

- About Us

- Case Studies

- 3D Laser Scanning & BIM

- Technipipe diversifies its activities using a FARO Laser Scanner

Technipipe diversifies its activities using a FARO Laser Scanner

Technipipe, a specialist in pipeline engineering, inspection and maintenance services, has won an international reputation for itself in the area of petroleum engineering. Its clients include many of the big names in the industry. Since they wanted to diversify their activities and open up new markets, Technipipe decided to enter the promising 3D laser scanning market and invested in the FARO 3D digitalization system: the FARO Laser Scanner.

Technipipe offers specialized engineering, inspection and maintenance services for pipelines. Using its experience in dealing with problems connected with the operation of pipelines, Technipipe rapidly branched out into project management and engineering for rerouting and overhauling pipelines, as well as projects to lay pipelines of short to medium length.

In addition, Technipipe regularly carries out design studies associated with pipelines: scraper stations or feasibility of scraping operations, as well as safety and risk studies. Technipipe's reference list includes many of the big names in the industry, such as Air Liquide, Arcelor, BP France, EDF GDF, SNCF – TGV, Total etc. Technipipe also boasts expertise in the areas of topography, cathode protection, pipeline inspection, and network monitoring, and wished to add 3D laser scanning to its portfolio of services. For this reason, in 2007, the company acquired a powerful 3D digitalisation system, the FARO Laser Scanner. With the acquisition of this new system, Technipipe is now in a position to offer 3D surveys using a precision technology based on laser scanning.

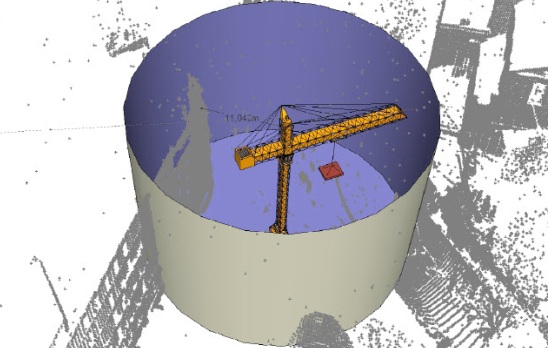

In a matter of minutes the local environment is captured in the form of a point cloud, each point accurate to the nearest millimetre, with a large range. The FARO Laser Scanner is a digitalisation system that employs laser technology. It executes a precise 3D survey of objects or of large interior spaces by sweeping through 360° and digitising everything that it encounters up to a distance of 120 m away in its line of vision. It captures millions of 3D measurements at a rate of 976,000 points/second and can generate complete 3D colour images in very little time, with each pixel being assigned XYZ coordinates that can be processed with FARO Scene, the program supplied with the device. The scan data means that it is then possible to perform direct measurements within the point cloud, to carry out analyses and to generate precise CAD models. Technipipe can thus measure distances, carry out planar studies and export the resulting scanned point cloud to Rhinoceros and Catia software. Laser scanning means that the surveyed environment can be accurately reproduced in 3D by processing the captured point cloud. The 3D model can be exported to the following programs: AutoCAD, Microstation, Catia, 3D Studio and SolidWorks. After 3D modelling, it is possible to create sections and perform conformity checks and risk analyses in the various areas of application, such as in the petrochemical industry, civil engineering, 3D archival or heritage inventorying. For example, Technipipe used the Laser Scanner to perform a preparatory study for the installation of a crane on a town centre site. One of its clients, a civil engineering company, planned to erect a crane there and wanted to study the available space with respect to the span and height of the crane. In a town centre, particularly because of safety restrictions, the rotation of the crane is limited by the buildings that surround the site. For this reason, the positions of the ridges of the surrounding buildings, the trees and the electricity poles must be known and mapped to determine the points where the crane should be fixed.

Gallery

Numbered points were therefore identified on the scan corresponding to the key points to be recorded as coordinates, in order to verify the feasibility of the installation of the crane. All the points scanned to the 3D laser were georeferenced, i.e. the position of each point in the scan is fixed in the Lambert coordinate system: the position in terms of X, Y and Z coordinates (elevation, sea level->Z=0). The capture of different 3D views allows a multitude of details to be identified from several angles, for example the road junction next to which the site is located. These different views not only enable the scene of activity to be ’photographed’ in 3D but also to locate the key points on the buildings and to visualize them very clearly. As the lengths are recorded and the precise coordinates of each point are known, it is possible to carry out supplementary measurements at the office without having to return to the site. This system offers a considerable saving in time, simplicity of operation and sufficient accuracy for this type of application. In this case, simply finding the XYZ coordinates of the critical points was enough to position the points on an existing AutoCAD plan. All that remained to be done in Auto- CAD was to draw a circle with a radius equal to the span of the crane and check the intersections with the XYZ coordinatesof the surveyed points.

4 Good Reasons:

A portable non-contact measurement system using laser technology to accurately capture measurements. The system rotates 360° and automatically measures everything within the line of sight from the scanner´s position.

-

Optical Measurement: The intelligent laser system carries out optical non-tactile measurements.

-

Resolution: The scanner creates an image with an extremely high resolution of up to 711 mio. pixel per scan.

-

Measuring Volume: The laser scanner captures measurements within a spherical radius range of up to 120 metres.

-

Portability: With a weight of 14.5kg the laser scanner is easy to transport.

Related Case Studies

-

Well-Connected Waterview Alliance / FARO Focus3D

Surveyor Mike Cutfield of Fletcher Construction has been utilising a FARO Focus3D high speed laser scanner for monitoring work around the tunnel portals on the enormous Waterview Connection ‘Roads of National Significance’ project in ...

Read More -

Otago University Nan Madol Runis

Faro Focus 3D Laser Scanner used on Otago School of Survey study of the Nan Madol ruins Micronesia for Humanities division of Otago University and National Geographic....

Read More