About Us

- Home

- About Us

- Case Studies

- Machine Control Technology

- Sitelink 3D gives BG Contracting the future, now

Sitelink 3D gives BG Contracting the future, now

Jason Bastings, engineering surveyor with Christchurch-headquartered BG Contracting, has long been an advocate for Topcon 3D-MC machine control technology; introducing the concept to the firm some years ago and overseeing its implementation on six machines since, including excavators, bulldozers and graders.

Now, with support from New Zealand Topcon distributor Synergy Positioning Systems, Jason and his team have furthered their transition to the digital job site with Topcon Sitelink3D, a complete site communication system providing data control, machine tracking and a comprehensive reporting system all in one.

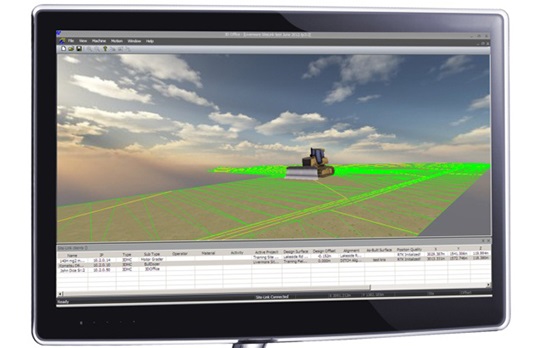

With Sitelink3D, Topcon has expanded its advanced 3D machine control systems to include remote machine support, job file transfer and real-time project management information.

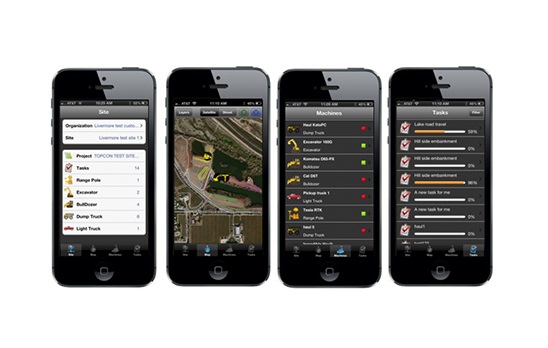

The system allows Jason to view all equipment on all BG Contracting job sites in real time from his office desktop and smart phone.

“Now that we are interconnected with all of our plant, we’re saving huge amounts of time in travel to and from site,” he says.

“I can look at our dozer or graders fitted with machine control from my office, see what surface the operator is using, what offset is being used, I can check how long the system was on ‘auto’ and how long the GPS has been on.”

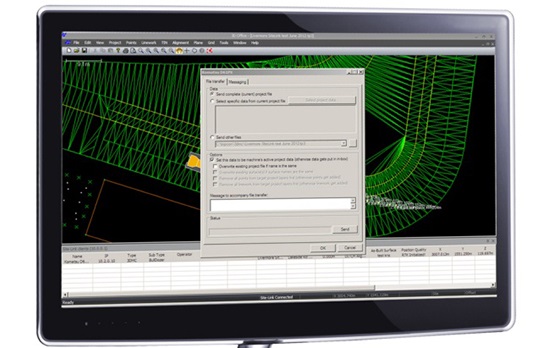

What’s more, should an update to a design be received from a consultant, Jason can download it into the machine control unit in the operator’s cab where it will automatically override the previous plan.

“We constantly have work on across the Christchurch region and beyond, so if I had to drive out to site with those plans, that could be a two or three hour chunk out of my day; now I’m simply uploading new data, awaiting a confirmation from my operator that it has all been received and getting on with something else,” Jason says.

Gallery

“With machine control, we get more than twice the productivity out of our machines and now with SiteLink3D, we have the ability to be more efficient with man hours on project management tasks too.”

Most in-field Topcon 3D-MC equipped machines are Sitelink 3D ready with the addition of an SL-100 radio modem. New 3D-MC systems can be ordered Sitelink 3D ready. Web based, real-time visualisation comes courtesy of Sitelink3D.net; a secure, subscription-based web portal that provides Jason with the ability to remotely access job site data, create new or update job site parameters, review real-time cut/fill mapping, acquire and store real-time survey data and view machine movement at any time.

Jason says that the overall system also comes into its own when tendering for new work; allowing him and his team to accurately estimate time and machine allowances, plan the transport logistics required, cut surveying costs and produce a fee that gives the stakeholder the assuredness of value.

“If you can snap back upwards of 10k of surveying costs on a large land development project, then that’s the sort of saving that puts you in a good place,” concludes Jason.

“There’s no doubt in my mind that every machine will feature machine control technology in the future. We really feel that we’re ahead of the game by linking it all together with SiteLink3D; the advantages it has given us with regards to the way we work, have made it a key future-proofing investment.”

For more information contact Synergy Positioning Systems or visit www.synergypositioning.co.nz/products

Back to all case studiesRelated Case Studies

-

Sitelink 3D Offers All-In-One Realtime Site Management

Sitelink 3D Offers All-In-One Realtime Site Management. Topcon Sitelink 3D is a complete site communication system providing data control, machine tracking and a comprehensive reporting system all in one. With Sitelink 3D, Topcon has expanded ...

Read More -

Multi-Machine Control’s a Winner for BG Contracting

Progressive Christchurch construction firm BG Contracting takes on a wide variety of roading, drainage, general earthworks and surveying work. No two projects are quite the same, with a multitude of disciplines requiring various skills and ...

Read More